|

|

|

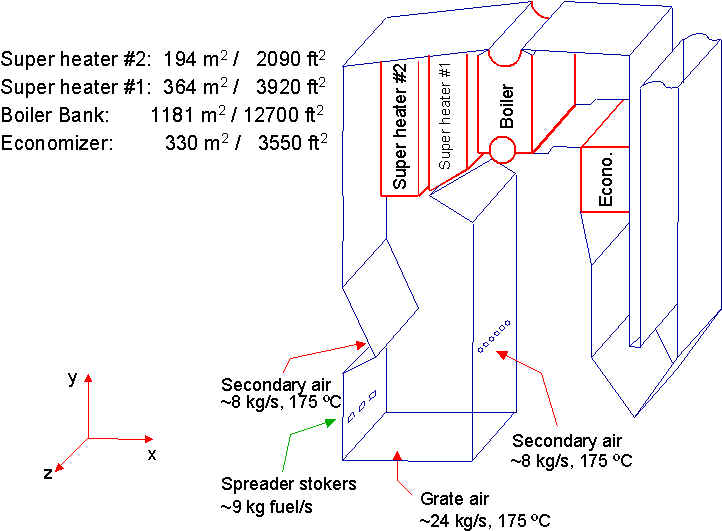

Dedicated biomass power generators use a variety of combustors to generate steam. We are involved in modeling several of these, with the examples on this page being from a stoker-fired grate. A schematic of the furnace is indicated in the first figure. It is of fairly typical design.

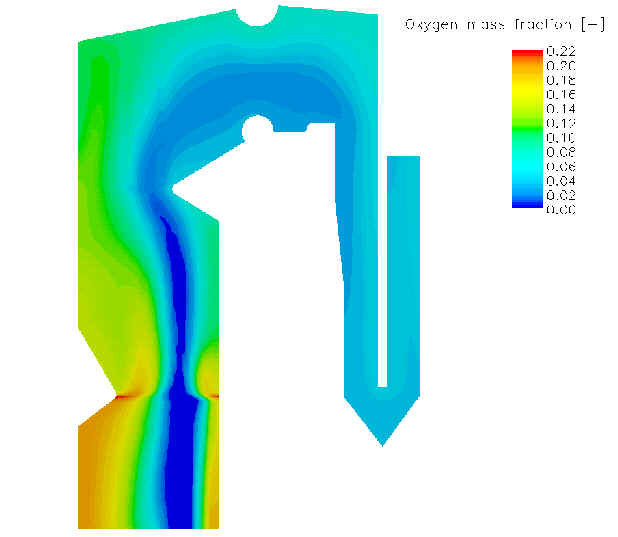

The fuel is fired onto the grate from the stokers. In this view, it moves from left to right. The fuel dries in flight (slightly) and on the grate (mostly), where it devolatilizes. The volatiles consume the local oxygen and create a plume of oxygen-depleted gases that do not fully mix until well past the furnace and convection pass exits. This lack of mixing contributes to high carbon in fly ash and high CO even when significant excess air is added to the furnace (typically 8-12% O2 in the flue gas).

The design of boiler and power plant systems involves attention to many different factors, all of which must be considered carefully so that the system is robust and efficient.

The CRF is involved in the design investigation of a power plant to be built in Belarus that uses contaminated biomass as a fuel. Since the biomass fuel to be used consists of contaminated wood and forest litter, there are special considerations. Presently, the conceptual design for a power plant that produces heat and power on a commercial scale is completed. The design is envisaged for the Svetlogorsk Power Plant, where it will replace an older natural gas fired unit. The wood-fired boiler is able to utilize the existing facilities (i.e. the steam turbines).

The other components of the plant will deviate from conventional wood-fired plants because of the radioactive contamination of the fuel. A separate feeding system is needed for the forest litter and duff, and the wood fuel needs an area for long term storage since wood chips tend to rot. Also, the plant would need a high performance filter system for the flue gas to collect the submicron cesium-containing particles formed. (A bag house with Gore-Tex fabric bags is believed to be an ideal choice.) In addition, the removal of the bottom ash from the boiler must not produce dust, and the ash needs to be disposed of in dedicated deposits that are in compliance with IAEA regulations.

Based on the analysis of the plant design, a biomass boiler for contaminated fuels seems feasible. We believe that if the plant is designed carefully, we will be able to address all the hazards for combustion of radioactive contaminated fuels. Preliminary engineering designs are currently underway for the suggested site at the Svetlogorsk Cogeneration Power Plant.

|

|

|