A new water-rocket launcher

The engineer in me thought it made a lot of sense to build a new launcher:

- One that grasps on the soda-bottle threads rather than the flange, making it possible to remove the flange to streamline a rocket and also making the launcher more robust in handling bottles with non-standard flange sizes.

- One that makes it easier and quicker to launch rockets.

- One that, like my modified Clark launcher, has flexibility regarding launch tubes and can fit inside a backpack.

The descriptions and pictures of Poppy Launcher here are not meant as a set of plans. However, on seeing this, perhaps you will be inspired to create your own design. (I take my inspiration wherever I can find it.) Note: if you are looking for a water-rocket launcher that's quick and easy to build, this is not it.

Carpe collum (“seize the neck”)

The launcher grasps and releases the bottle threads using a “split collet” or “quick release” design. This is not different in general principle than most launcher designs. The releasing action is illustrated in the following video:

Click on the above image to play the 362KB DivX-encoded AVI file. The movie runs natively at 60 frames per second, but can be played at slower speeds using a player such as Irfanview.

The assembled head unit mounted on the base:

The head unit attached to a bottle:

The assembled head unit is easily removed from the base. This allows the head to be attached to an inverted rocket, so that water does not spill out. Basically, the bottle screws onto the head just like one would install a light bulb in a socket. Nothing could be quicker or easier.

The disassembled head unit:

The pull lever is made of acrylic, which can be shaped when heated. The trigger ring and “bare” head units are made mostly of PVC plumbing parts. The head is pressure-tight and seals against the bottom of the bottle with an o-ring. I used a lathe to cut a precision groove for the o-ring. A Shraeder valve on the head allows pressurized gas to be added to the rocket.

Collet piece #3 is removed to show the arrangement

of the other pieces about the head:

The four red collet pieces were originally a Tornado Tube®—my Dremel tool brought about the transformation. With the trigger ring in place, the force of the pressurized bottle cannot pull the collet pieces out of the head unit, due to mutually opposing ledges between the “bare” head and collet pieces.

Interchangeable launch tubes

Poppy Launcher is designed so that launch tubes can be interchanged or not used at all. This allows different size bottles to be used, or special nozzles to be attached to the rockets. Four launch tubes were constructed from 1/2-inch schedule-40 PVC pipe. One end of each launch tube is cut on a lathe to have a narrowed diameter that fits snugly into the bore of the head unit. In addition, the longest launch tube is reamed-out on the opposite end so that any one of the shorter launch tubes will fit into it, much like the way tent poles fit together. This creates an extra long launch tube when needed.

Launch-tube configurations:

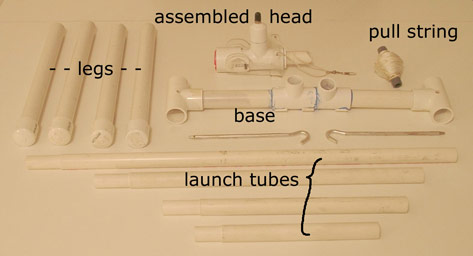

The pieces of Poppy Launcher:

The head unit slips onto the base in one of two locations, one that is vertical and another that is off-vertical. An off-vertical launching angle is nice for countering wind, or when you want the rocket to land away from the launching location. A few of the pictures above show the head unit fitted onto the vertical mount.

The base has four removable legs and when assembled looks like the letter H. For additional stability, there are two holes in the base through which metal stakes can secure the unit to the ground. All of the pieces shown above can easily fit into a backpack.

Poppy Launcher

Poppy Launcher